Parsimony - Sourcing 101 - The vFLOW method

Learning how to use the best practices in sourcing is easier than you think.

Sourcing in 2024 with a Dash of vFLOW (and a Pinch of Humor)

·

Apr 5

·

Welcome aboard the vFLOW method – short for Vendor Freight Logistics Optimization Worldwide – where sourcing in 2024 is less about navigating a maze of complex jargon and more about keeping things light, professional, and yes, even spiced with a bit of humor. Imagine vFLOW as your trusty GPS for global sourcing: it won't let you down, even when the road gets bumpy with economic potholes.

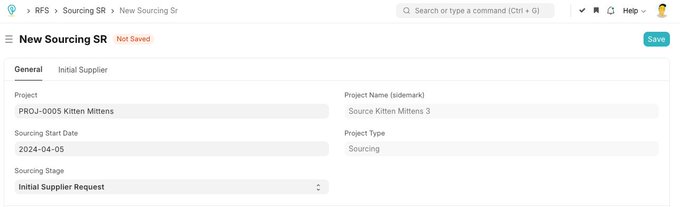

Hunting down a new supplier? Think of it as speed dating for business. Start by creating a sourcing process. What are you sourcing? Is it linked to any existing project? Where are you in the process?

PROCESS DEEP DIVE

Sourcing Phase 1 - Name It

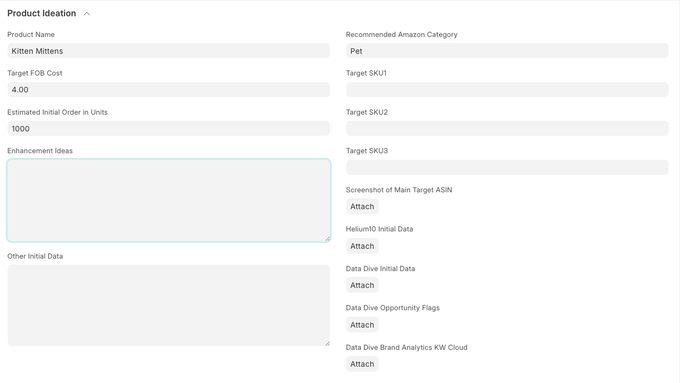

Next focus on the product you're trying to deliver. That means having a sense of your competition and how you intend to set yourself apart. Having research tools like Helium10 and/or DataDive can be decisive in cutting down your assessment of the overall market and the product opportunity itself. We would always recommend documenting the initial research data, your target SKUs, and other thoughts that you have at the time of ideation. You may not remember the details later, and more importantly, this allows you to share with anyone on the team.

Sourcing Phase 1 - Ideation

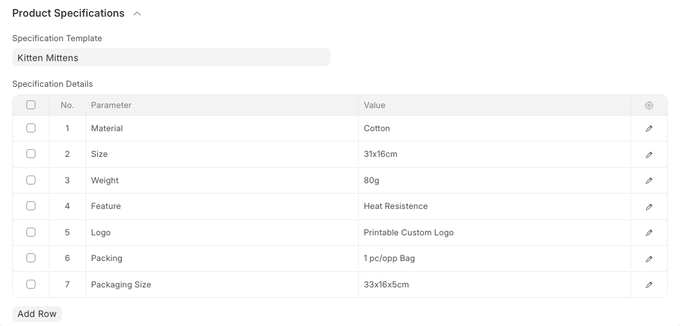

Next you should set about to determine the basic specifications of your new item. The premise is that you should have a starting target to align all potential sourcing prospects to the same spec. This is just the beginning so you can expect this to evolve, if not during the sourcing process, it will evolve with each subsequent order at the supplier. Ideally your process will allow you to define a template of specifications that you can update and reuse over time.

Sourcing Phase 1 - Specification

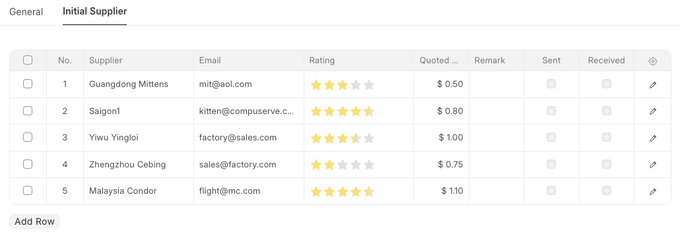

Now that you've set the groundwork go forward and line up a good mix of candidates – let's say 5 to 10 – and see who clicks with you. You're looking for a connection that sparks more than just polite conversation; you need a supplier who gets your jokes and your business needs. Price is only one variable. What about responsiveness? What about their capacity? What about their length of business, number of employees, credit rating, etc...? Your assessment should be comprehensive. If you just go to the lowest price - you will get what you pay for.

We always recommend a good process that you solicit quotations based on the same specification from each supplier. Consistency is vital when you think about comparing apples to apples. Ideally you have templates that you can use for each phase of the supplier interaction.

Sourcing Phase 2 - Communication

Having a solid prospective supplier list is very important. And tracking the progress of the communication and the interactions in a system that can be shared between your team we also believe is critical to scale. After all, team members from around the world can watch the progress in real time as the data flows into the system and augment and participate to add value.

Sourcing Phase 2 - Initial Supplier

It's time for the "Sample Showdown," where you shuffle through the wares of your potential supply suitors. Like flipping through a menu, you'll sample a little nibble from column A, a taste from column B, and decide who gets to cook for your next big dinner party – I mean, product launch.

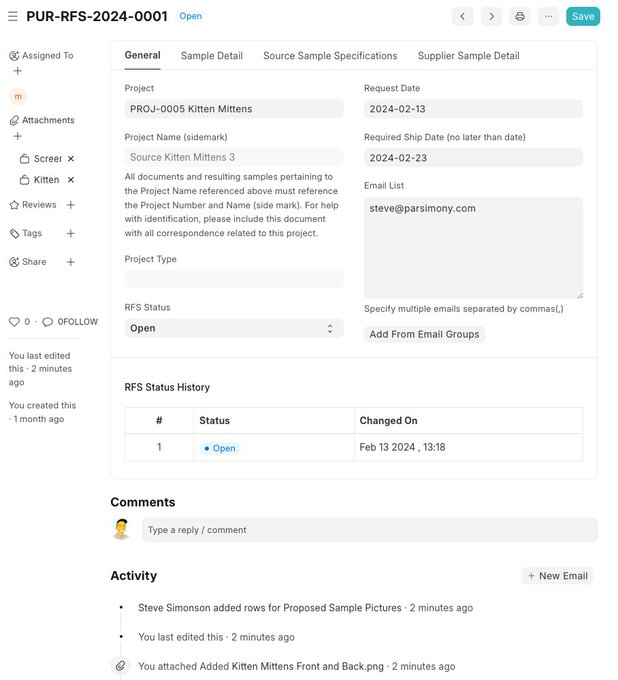

Managing a sample process is vital. Request for Sample (RFS) is the preferred

method of managing the FLOW.

Sourcing Phase 3 - RFS General

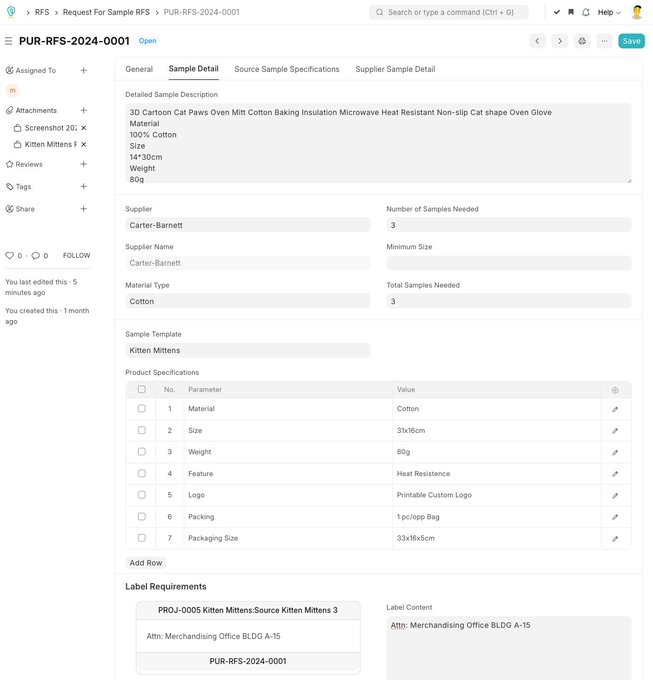

Don't forget that each sample you order needs to provide sufficient details to keep your results consistent, otherwise the process will take longer and cost more.

Sourcing Phase 3 - RFS Sample Detail

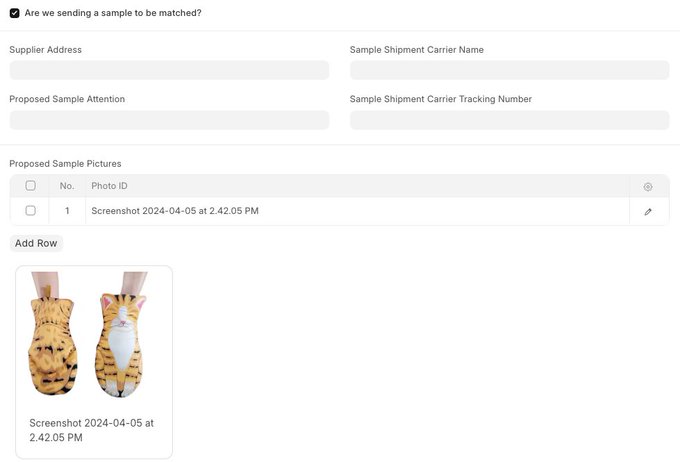

Beyond the basics, if you have a sample to be sent, be sure you document the shipping details and tracking information to each supplier. Bring photos to the table as well. They say pictures are worth a 1000 words in every day talk, but in supply chain pictures are worth 1000 hours of time. Skip to the end and show them the overall concept and then you can articulate changes and details you want.

Sourcing Phase 3 - Source Sample Specifications

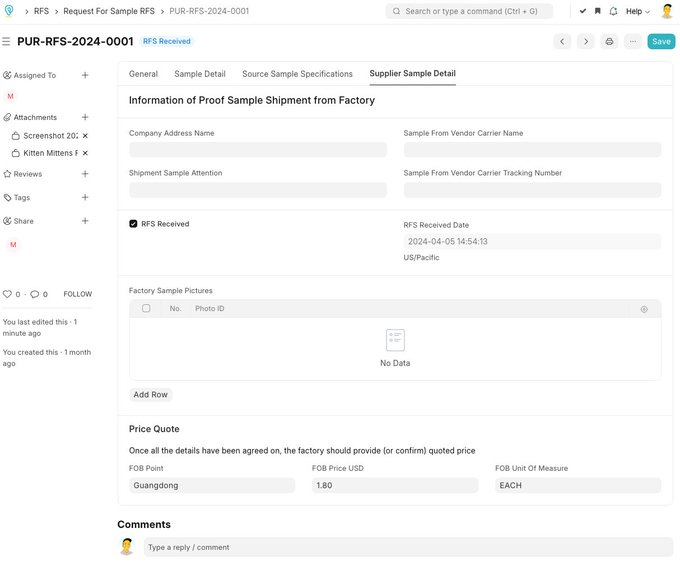

And before we finish sharing the FLOW framework we should point out that the collection of the inbound supplier sample shipment should also be entered into your system:

Sourcing Phase 3 - Supplier Sample Detail

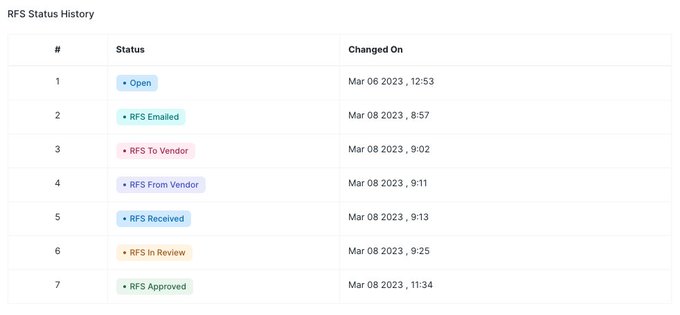

Managers matter too. Giving the leaders of the sourcing org as well as the project owner themselves a clear understanding of the history and status of an RFS is vital. Think about how to provide that visibility both in the project itself:

Sourcing Individual Project Overview

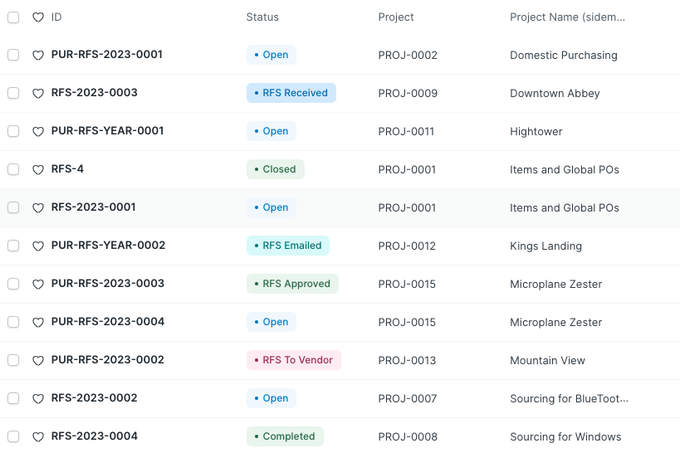

But don't forget when you have lots of samples you want to be able to see a quick view of the status of all of them in a list view:

Sourcing Individual Project List View

PROCESS WRAP UP

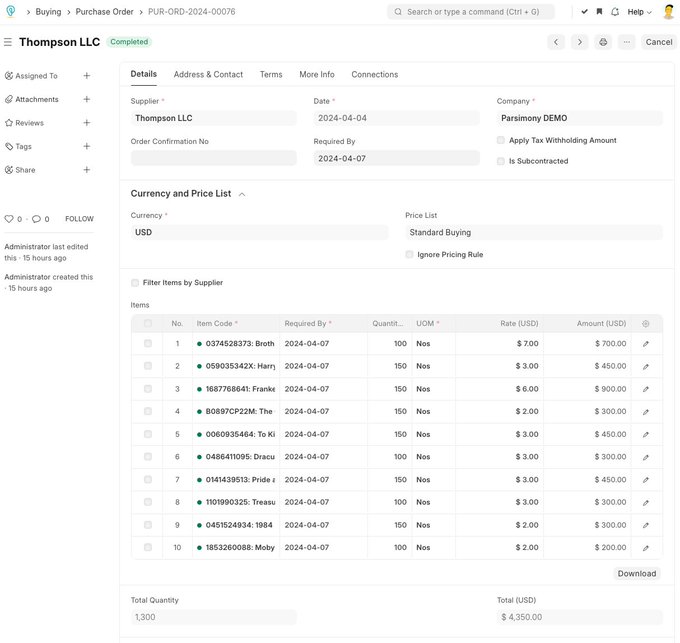

Now, let's talk money without making your head spin. Pricing can fluctuate like your mood on a Monday morning – you've got raw materials, labor, and energy to consider. If the price of your main ingredient – let's call it cotton – is making a run for it, you'll need to chat with your supplier like they're your barista charging extra for oat milk. Get into the details and validate the story. If the commodity is not increasing then push for why there is a price increase. If the commodity is falling ask for discounts at appropriate intervals. Use pricing lists and agreements to manage this and don't forget to index those with each Purchase Order.

Purchase Order Line Item View

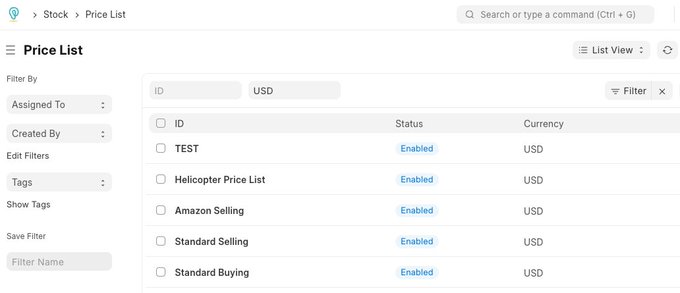

Currency conversion is the wildcard, folks. It's like a seesaw; if the US dollar is up, you feel like a star, but if it's down, it's like realizing you've been walking around with spinach in your teeth. Keep an eye on it, or it'll sneak up on you. We recommend indexing the currency with every PO. Use price lists for each selling channel, each buying channel, and wherever changes are appropriate to systemically manage the margins.

Price List - List View

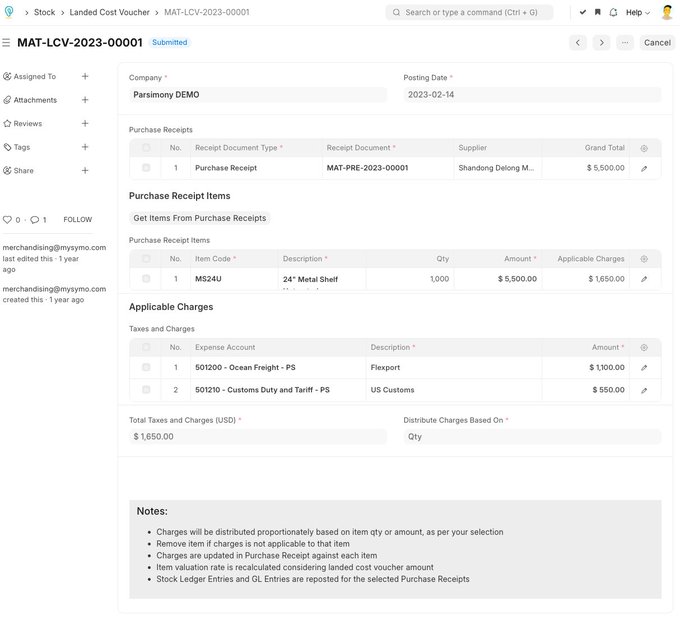

Shipping prices? They're the uninvited plus-one to your party. They can change faster than your playlist at a house party. If they're part of the deal, make sure their dance moves aren't going to step on your toes. Use a proper accounting method to be certain you are tracking ACTUAL landed costs. The assignment of freight, duties, customs, etc.. should be done in a systemic way.

Landed Cost Voucher

Here's the vFLOW kicker: decisions should be driven by cold hard facts, not by the heat of the moment. If your supplier's whispering sweet nothings about price hikes, don't write a breakup song yet. Ask why, dig deep, and see if it's just a mix-up or if the market's playing a different tune. If you'll notice we track the data so we can make decisions based on facts instead of emotions.

In the end, sourcing's all about the handshakes, not the headaches. Aim for a happy medium where neither side feels like they're leaving the party empty-handed. With vFLOW, it's about steering your sourcing ship into the sunset, high-fiving the dolphins along the way, and knowing that everyone's onboard for the journey ahead. Keep it light, keep it smart, and let’s make sure everyone's still friends when the sun rises on another day of global business. To see

in hundreds of video bite sized chunks check out the

youtube page.

Steve Simonson

Steve Simonson is a lifetime entrepreneur having founded, purchased, built, and sold numerous companies over the past 3 decades. Along the way Steve’s companies have been publicly recognized with three consecutive years on the Inc. 500 list, multiple listings on the Internet Retailer Top 500, Washington State Fastest Growing Business as well as a number of other company accolades. Steve was also a finalist in the Ernst and Young Entrepreneur of the Year Award. Steve brings his deep expertise as a leader and operator at many companies which he has taken to from start-up to exit. To learn more check out https://stevensimonson.com and https://catalyst88.com and https://symoglobal.com

No comments yet. Login to start a new discussion Start a new discussion